RXR-M 30D fire fighting dry powder fire extinguishing robot

Product overview

RXR-M 30D fire fighting dry powder fire extinguishing robot as a powder material fire extinguishing robot such as jet dry powder or cement powder, using lithium battery power supply as power supply, using wireless remote control to control powder material robot from a long distance. Be able to connect with powder truck and spray powder to extinguish fire. Can be used in a variety of large petrochemical enterprises, tunnels, subways and other increasing, oil gas, gas leakage and explosion, tunnel, subway collapse and other disaster hazards, fire fighting robots play an important role in emergency rescue, mainly replace firefighters in dangerous fire site or smoke fire scene rescue special equipment.

Scope of use

● Fire Rescue in Large Petroleum and Chemical Enterprises

● Fires caused by combustible gases, flammable liquids, organic solvents, electrical equipment, etc

● Applicable places are: oil fields, oil depots, oil refineries, chemical plants, chemical warehouses, airports and industrial and mining enterprises

Product characteristics

1.★ protection grade

The chassis protection grade is IP65 IP 67、 the whole machine protection grade

2.★ fast

4.32 Km/ hours

3.★ multifunctional uses

Fire fighting, reconnaissance

Key technical indicators

4.1 Robots:

1.Name: Fire Dry Powder Fire Fighting Robot

2.Model: RXR-M 30D

3.Basic functions: fire fighting, environmental reconnaissance in disaster areas;

4.Enforcement of Fire Industry Standards: General Technical Conditions for GA 892.1-2010 Fire Robots Part 1

5.Power: Electric, ternary lithium battery

6.★ size :≤ length 1670 mm× width 940 mm× height 1350

7.★ steering diameter: mm ≤1767

8.★ weight: kg ≤396

9.★ traction: N ≥2840

10.★ line maximum speed :≥1.2 m/s, remote control stepless speed

11.★ running deviation :≤1.74%

12.Brake distance :≤ m 0.16

13.★ climbing capacity :≥70 per cent (or 35°)

14.Overhead height :≥ mm,220

15.≥30 degrees

16.★ wading depth: mm ≥400

17.Duration :2 h

18.Reliability Time: Passed 16 hours continuous stability reliability test

19.Distance :1000 m

20.Video transmission distance :1000 m

21.Automatic power generation, recoil automatic suppression function: the main motor of the robot uses power generation brake, in the fire-extinguishing jet will be recoil into electric energy;

22.★ robot crawler: fire robot crawler should adopt flame retardant anti-static high temperature resistant rubber; the inside of crawler is metal skeleton; it has crawler anti-stripping protection design;

23.Waterproof belt knotting function (optional): through double universal structure, can rotate 360 degrees to prevent water belt knotting

24.Automatic shedding function of water belt (optional): remote control operation realizes automatic shedding water belt to ensure that the robot can return lightly after completing the task

25.Control Terminal: Hand-held Digital Integrated Remote Control Terminal

4.2 Robot fire extinguishing systems:

1.Fire Gun: Domestic Explosion-proof Fire Dry Powder Gun

2.Type of extinguishing agent: dry powder, cement powder, etc

3.Material: Gun body – stainless steel, gun head – aluminum alloy hard oxidation

4.Working pressure (Mpa):0.5~1.6(Mpa)

5.★ jet flow :30 kg/s

6.Range (m):35 m

7.★ rotation angle: horizontal-90°~90°, vertical 0°~90

8.Random camera: with water gun servo camera, camera resolution 1080 P, wide angle 60°

9.Infrared heat source tracking function (optional): with infrared heat source tracking function, through infrared thermal imaging of heat source detection and tracking.

4.3 Robo system:

Through the configuration of gas instrumentation, environmental monitoring module, infrared camera, infrared thermal imager, pickup and other vehicle equipment, can be the scene of the accident of toxic and harmful gases, environmental conditions in disaster areas, video, audio remote reconnaissance; equipped with explosion-proof lifting platform equipped with environmental detection sensors and cameras, to achieve different heights of toxic flammable gases, audio and video, environmental analysis.

1.Reconnaissance system configuration: vehicle explosion-proof infrared camera 1; rotating infrared cloud head 1, cloud head horizontal rotation 360 degrees, up and down rotation -20~95 degrees

2.★ gas and environment sensing detection module (optional): loading wireless emergency rescue rapid deployment detection system and temperature and humidity detector, can detect: CO2: 0-5 per cent VOL

CH4: VOL 0-100 per cent

CO: 0-1000 ppm

H2S: 0-100 ppm

CL2: 0-1000 ppm

NH3: 0-100 ppm

O2: 0-30% O2

H2: 0-1000 ppm

Temperature range: -25°C to 60°C C

Humidity range: RH to 90 per cent RH 0 per cent

4.4 Robot video and audio perception:

1.Number and configuration of cameras: the video system is composed of 2 fixed high-definition infrared cameras in the fuselage to realize the 360-degree panoramic image of the robot body before and after observation;

2.Camera illumination: fuselage camera can provide clear image at 0.001 LUX low illumination, dynamic anti-shake, camera should have zero illumination can effectively and clearly collect the scene situation, and display on the LCD screen of the operating terminal

3.Camera pixels: million HD images, resolution 1080 P, wide angle 60°

4.★ Camera Protection Level: IP68

5.Infrared thermal imager (optional): equipped with infrared thermal imager to detect and track the heat source; infrared thermal imager has the function of image anti-jitter; it has the function of image acquisition and real-time transmission; it has the function of visual fire source search. And the testing equipment must be explosion-proof, the original certificate for reference

4.5 Remote control terminal configuration parameters

1.Dimensions :406*330*174 mm

2.Full weight :8.5 kg

3.Display screen: No less than 10 inch high brightness LCD screen ,2 channels video signal switching

4.Hours of work :8 h

5.Basic functions: remote control and monitor integrated portable design, matching ergonomics strap; can be viewed and controlled at the same time, the environment around the scene image stable presentation to the distant operator, can real-time display battery power, control robot forward, backward, steering and other movements; control dry powder gun up, down, left, right, self-swing and other actions.It has the function of image anti-jitter and 360 degree image acquisition and real-time transmission in front, rear and around the robot. The data transmission mode is wireless transmission using encrypted signal.

6.Walking control function: through a two-axis industrial rocker, realize the robot forward, backward, left turn, right turn flexible operation

7.Camera control function: there is a two-axis industrial rocker, a rocker can control the head up, down, left, right action

8.Powder gun control function: Yes, self reset point switch

9.Video Switch: Self-reset Point Switch

10.Control of automatic towing function: realized by self-reset point switch

11.Lighting control function: through the self-reset point switch, the upper computer self-locking response to achieve

12.Auxiliary tools: Handheld remote control terminal shoulder strap, mobile tripod

4.6 Internet functionality:

1.GPS function (optional): GPS location, track can be queried

2.★ can access the robot cloud management platform (optional): the robot name, model, manufacturer, GPS location, battery power, video, temperature, humidity, CO2、CO、H2S、CH4、CL2、NH3、O2、H2 data can be transmitted to the cloud management platform through 4 G/5G network, and the robot status can be consulted in real time by PC/ the mobile phone end. It is convenient for command personnel to make decisions and equipment managers to manage the whole life cycle of robots

4.7 Other:

★ emergency transportation scheme (optional): robot special transport trailer or robot special transport vehicle

Product configuration

1.Fire fighting robot ×1

2.1× remote control terminal

3.Car body charger (54.6 V)×1 set

4.Remote control charger (24 V)×1 set

5.Antenna (digital transmission)×2

6.Antenna (transmission)×3

7.Robot cloud management platform ×1 set (optional)

8.Robot emergency transport vehicle ×1(optional)

VI. Product certification

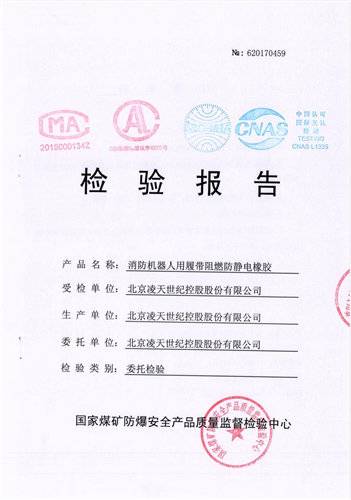

1.Inspection report of crawler material for ★ fire-fighting robot: inspection report of national coal mine explosion-proof safety product quality supervision and inspection center

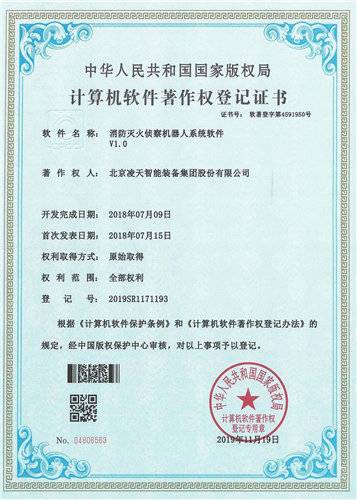

2.★ has fire-fighting robot system software, computer software copyright registration certificate, provide the original certificate for reference.

Certificates and Reports